Folic acid,59-30-3

Folic acid,59-30-3

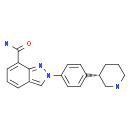

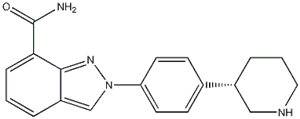

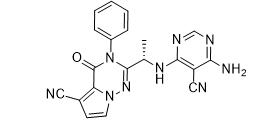

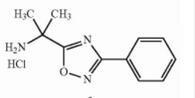

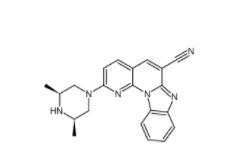

MK-4827 (HCl)

MK-4827 (HCl)

Folic acid

Folic acid

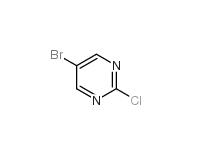

5-Bromo-2-chloropyrimidine 32779-36-5

5-Bromo-2-chloropyrimidine 32779-36-5

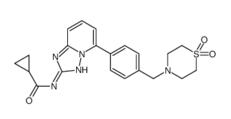

Niraparib

Niraparib

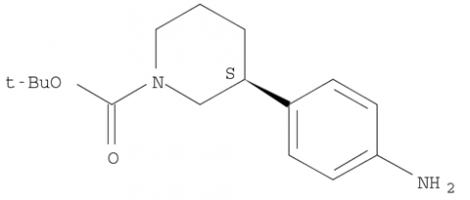

(R)-tert-butyl 3-(4-aminophenyl)piperidine-1-carboxylate

(R)-tert-butyl 3-(4-aminophenyl)piperidine-1-carboxylate

(R)-tert-butyl 3-(4-aMinophenyl)piperidine-1-carboxylate

(R)-tert-butyl 3-(4-aMinophenyl)piperidine-1-carboxylate

tert-butyl 3-(4-aminophenyl)piperidine-1-carboxylate

tert-butyl 3-(4-aminophenyl)piperidine-1-carboxylate

![(3S)-3-[4-[7-[[(1,1-Dimethylethyl)amino]carbonyl]-2H-indazol-2-yl]phenyl]-1-piperidinecarboxylic acid 1,1-dimethylethyl ester (3S)-3-[4-[7-[[(1,1-Dimethylethyl)amino]carbonyl]-2H-indazol-2-yl]phenyl]-1-piperidinecarboxylic acid 1,1-dimethylethyl ester](/data/attachment/201705/26/3446bd2b841689a5afc36447418dc476.png) (3S)-3-[4-[7-[[(1,1-Dimethylethyl)amino]carbonyl]-2H-indazol-2-yl]phenyl]-1-piperidinecarboxylic acid 1,1-dimethylethyl ester

(3S)-3-[4-[7-[[(1,1-Dimethylethyl)amino]carbonyl]-2H-indazol-2-yl]phenyl]-1-piperidinecarboxylic acid 1,1-dimethylethyl ester

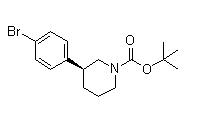

(3S)-3-(4-Bromophenyl)-1-piperidinecarboxylic acid 1,1-dimethylethyl ester

(3S)-3-(4-Bromophenyl)-1-piperidinecarboxylic acid 1,1-dimethylethyl ester

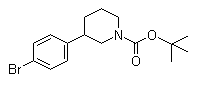

3-(4-Bromophenyl)piperidine-1-carboxylic acid tert-butyl ester

3-(4-Bromophenyl)piperidine-1-carboxylic acid tert-butyl ester

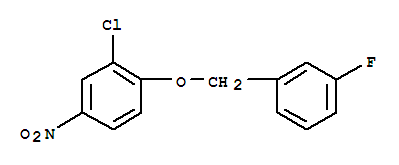

3-Chloro-4-(3-fluorobenzyloxy)nitrobenzene

3-Chloro-4-(3-fluorobenzyloxy)nitrobenzene

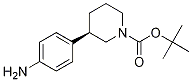

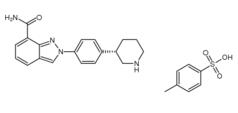

Niraparib p-toluenesulfonate

Niraparib p-toluenesulfonate

![N-(1,1-Dimethylethyl)-2-[4-(3S)-3-piperidinylphenyl]-2H-indazole-7-carboxamide N-(1,1-Dimethylethyl)-2-[4-(3S)-3-piperidinylphenyl]-2H-indazole-7-carboxamide](/data/attachment/201705/26/da41ae70b523a458db70333bd1059362.png) N-(1,1-Dimethylethyl)-2-[4-(3S)-3-piperidinylphenyl]-2H-indazole-7-carboxamide

N-(1,1-Dimethylethyl)-2-[4-(3S)-3-piperidinylphenyl]-2H-indazole-7-carboxamide

![2-{4-[(3S)-piperidin-3-yl]phenyl}-2H-indazole-7-carboxamide 2-{4-[(3S)-piperidin-3-yl]phenyl}-2H-indazole-7-carboxamide](/data/attachment/201705/26/d3114dd994f3dda3142cba7d326bcede.jpg) 2-{4-[(3S)-piperidin-3-yl]phenyl}-2H-indazole-7-carboxamide

2-{4-[(3S)-piperidin-3-yl]phenyl}-2H-indazole-7-carboxamide

Alectinib

Alectinib

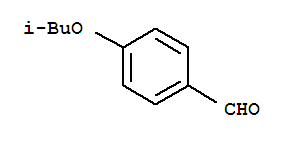

Benzaldehyde,4-(2-methylpropoxy)

Benzaldehyde,4-(2-methylpropoxy)

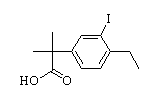

2-(4-ethyl-3-iodophenyl)-2-Methylpropanoic acid

2-(4-ethyl-3-iodophenyl)-2-Methylpropanoic acid

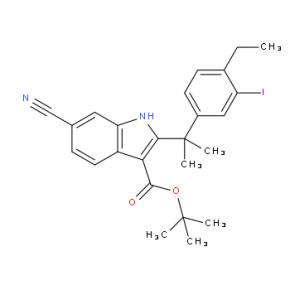

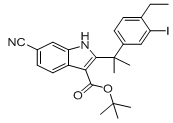

tert-butyl 6-cyano-2-(2-(4-ethyl-3-iodophenyl)propan-2-yl)-1H-indole-3-carboxylate

tert-butyl 6-cyano-2-(2-(4-ethyl-3-iodophenyl)propan-2-yl)-1H-indole-3-carboxylate

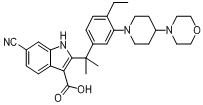

6-cyano-2-(2-(4-ethyl-3-(4-morpholinopiperidin-1-yl)phenyl)propan-2-yl)-1H-indole-3-carboxylic acid

6-cyano-2-(2-(4-ethyl-3-(4-morpholinopiperidin-1-yl)phenyl)propan-2-yl)-1H-indole-3-carboxylic acid

![9-ethyl-8-iodo-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile 9-ethyl-8-iodo-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile](/data/attachment/201705/28/e48e5d316800efe6192ebfdeec6cf28c.gif) 9-ethyl-8-iodo-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile

9-ethyl-8-iodo-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile

6-broMo-7-Methoxy-1,1-diMethyl-3,4-dihydronaphthalen-2(1H)-one

6-broMo-7-Methoxy-1,1-diMethyl-3,4-dihydronaphthalen-2(1H)-one

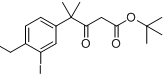

tert-butyl 4-(4-ethyl-3-iodophenyl)-4-methyl-3-oxopentanoate

tert-butyl 4-(4-ethyl-3-iodophenyl)-4-methyl-3-oxopentanoate

![9-broMo-8-hydroxy-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile 9-broMo-8-hydroxy-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile](/data/attachment/201705/28/fe98529212eb834b17a38f13138a35bf.png) 9-broMo-8-hydroxy-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile

9-broMo-8-hydroxy-6,6-diMethyl-11-oxo-6,11-dihydro-5H-benzo[b]carbazole-3-carbonitrile

![9-ethyl-6,6-diMethyl-8-(4-Morpholinopiperidin-1-yl)-11-oxo-5a,6,11,11a-tetrahydro-5H-benzo[b]carbazole-3-carbonitrile hydrochloride 9-ethyl-6,6-diMethyl-8-(4-Morpholinopiperidin-1-yl)-11-oxo-5a,6,11,11a-tetrahydro-5H-benzo[b]carbazole-3-carbonitrile hydrochloride](/data/attachment/201705/28/36e5363f0c9f92378b75195743e2abb2.jpg) 9-ethyl-6,6-diMethyl-8-(4-Morpholinopiperidin-1-yl)-11-oxo-5a,6,11,11a-tetrahydro-5H-benzo[b]carbazole-3-carbonitrile hydrochloride

9-ethyl-6,6-diMethyl-8-(4-Morpholinopiperidin-1-yl)-11-oxo-5a,6,11,11a-tetrahydro-5H-benzo[b]carbazole-3-carbonitrile hydrochloride

tert-butyl 6-cyano-2-(2-(4-ethyl-3-iodophenyl)propan-2-yl)-1H-indole-3-carboxylate

tert-butyl 6-cyano-2-(2-(4-ethyl-3-iodophenyl)propan-2-yl)-1H-indole-3-carboxylate

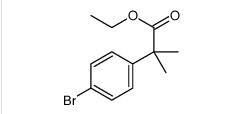

ethyl 2-(4-broMophenyl)-2-Methylpropanoate

ethyl 2-(4-broMophenyl)-2-Methylpropanoate

ert-Butyl (4R-cis)-6-formaldehydel-2,2-dimethyl-1,3-dioxane-4-acetate

ert-Butyl (4R-cis)-6-formaldehydel-2,2-dimethyl-1,3-dioxane-4-acetate

(2S)-Hydroxy(phenyl)acetic acid (2R)-N-benzyl-1-(4-methoxyphenyl)propan-2-amine

(2S)-Hydroxy(phenyl)acetic acid (2R)-N-benzyl-1-(4-methoxyphenyl)propan-2-amine

5-Tosyladenosine

5-Tosyladenosine

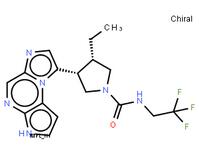

Filgotinib

Filgotinib

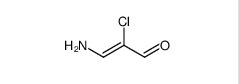

3-amino-2-chloroacrolein

3-amino-2-chloroacrolein

![2-Methylpyrazolo[1,5-a]pyrimidine-6-carboxamide 2-Methylpyrazolo[1,5-a]pyrimidine-6-carboxamide](/data/attachment/201706/03/2e19d959128718d26901f9909d7b9342.jpg) 2-Methylpyrazolo[1,5-a]pyrimidine-6-carboxamide

2-Methylpyrazolo[1,5-a]pyrimidine-6-carboxamide

![11-(1-Methylpiperidin-4-ylidene)-6,11-dihydro-5H-benzo[d]iMidazo[1,2-a]azepine 11-(1-Methylpiperidin-4-ylidene)-6,11-dihydro-5H-benzo[d]iMidazo[1,2-a]azepine](/data/attachment/201706/03/1549d9affee63ead337049001f25d9fa.jpg) 11-(1-Methylpiperidin-4-ylidene)-6,11-dihydro-5H-benzo[d]iMidazo[1,2-a]azepine

11-(1-Methylpiperidin-4-ylidene)-6,11-dihydro-5H-benzo[d]iMidazo[1,2-a]azepine

1-(4-(1-PHENETHYL-1H-IMIDAZOLE-2-CARBONYL)PIPERIDIN-1-YL)ETHANONE

1-(4-(1-PHENETHYL-1H-IMIDAZOLE-2-CARBONYL)PIPERIDIN-1-YL)ETHANONE

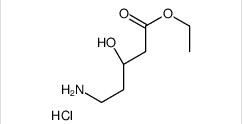

ethyl (3R)-5-amino-3-hydroxypentanoate,hydrochloride

ethyl (3R)-5-amino-3-hydroxypentanoate,hydrochloride

LAS191954 free base

LAS191954 free base

![tert-butyl 5-tosyl-5H-pyrrolo[2,3-b]pyrazin-2-ylcarbamate tert-butyl 5-tosyl-5H-pyrrolo[2,3-b]pyrazin-2-ylcarbamate](/data/attachment/201706/03/8a3c0fcdeb9ed744fc854cf248d4d53e.jpg) tert-butyl 5-tosyl-5H-pyrrolo[2,3-b]pyrazin-2-ylcarbamate

tert-butyl 5-tosyl-5H-pyrrolo[2,3-b]pyrazin-2-ylcarbamate

ABT-494 Intermeidate N-2

ABT-494 Intermeidate N-2

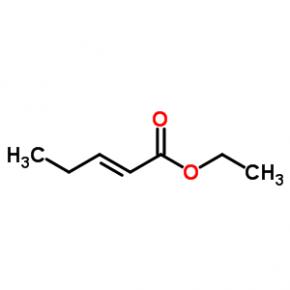

ethyl (2E)-pent-2-enoate

ethyl (2E)-pent-2-enoate

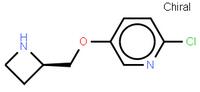

abt594 Intermediate

abt594 Intermediate

LOXO101 Intermediate 2

LOXO101 Intermediate 2

LOXO101 Intermediate 1

LOXO101 Intermediate 1

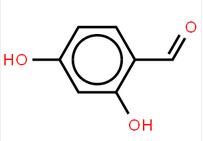

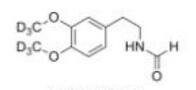

Deutetrabenazine intermediate N-2

Deutetrabenazine intermediate N-2

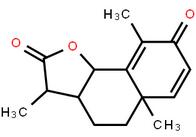

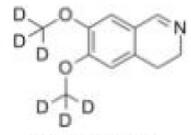

Deutetrabenazine intermediate N-1

Deutetrabenazine intermediate N-1

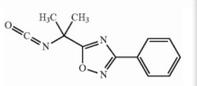

Naldemedine tosylate intermediate

Naldemedine tosylate intermediate

Naldemedine tosylate intermediate N-2

Naldemedine tosylate intermediate N-2

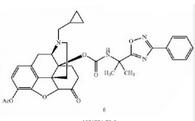

Naldemedine

Naldemedine

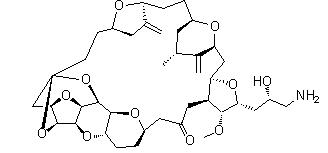

Eribulin

Eribulin

![2-Furanpropanol, 5-[2-[(2S,4R,6R)-6-[[(2S,3S,4R,5R)-5-[(2S)-2,3-bis[[(1,1-dimethylethyl)dimethylsilyl]oxy]propyl]tetrahydro-4-methoxy-3-[(phenylsulfonyl) methyl]-2-furanyl]methyl]tetrahydro-4-methyl-5-methylene-2H-pyran-2-yl]ethyl]tetrahydro-4-methylene-, 2-Furanpropanol, 5-[2-[(2S,4R,6R)-6-[[(2S,3S,4R,5R)-5-[(2S)-2,3-bis[[(1,1-dimethylethyl)dimethylsilyl]oxy]propyl]tetrahydro-4-methoxy-3-[(phenylsulfonyl) methyl]-2-furanyl]methyl]tetrahydro-4-methyl-5-methylene-2H-pyran-2-yl]ethyl]tetrahydro-4-methylene-,](/data/attachment/201706/03/3575f40dcc389832ca73cc99972a645b.gif.thumb.jpg) 2-Furanpropanol, 5-[2-[(2S,4R,6R)-6-[[(2S,3S,4R,5R)-5-[(2S)-2,3-bis[[(1,1-dimethylethyl)dimethylsilyl]oxy]propyl]tetrahydro-4-methoxy-3-[(phenylsulfonyl) methyl]-2-furanyl]methyl]tetrahydro-4-methyl-5-methylene-2H-pyran-2-yl]ethyl]tetrahydro-4-methylene-,

2-Furanpropanol, 5-[2-[(2S,4R,6R)-6-[[(2S,3S,4R,5R)-5-[(2S)-2,3-bis[[(1,1-dimethylethyl)dimethylsilyl]oxy]propyl]tetrahydro-4-methoxy-3-[(phenylsulfonyl) methyl]-2-furanyl]methyl]tetrahydro-4-methyl-5-methylene-2H-pyran-2-yl]ethyl]tetrahydro-4-methylene-,

2-BroMo-1-quinolin-6-yl-ethanone

2-BroMo-1-quinolin-6-yl-ethanone

![6-[(6-Bromo-1H-[1,2,3]triazolo[4,5-b]pyrazin-1-yl)methyl]-7-fluoroquinoline 6-[(6-Bromo-1H-[1,2,3]triazolo[4,5-b]pyrazin-1-yl)methyl]-7-fluoroquinoline](/data/attachment/201706/07/27ae4307b53f4294590fb8f914894490.jpg) 6-[(6-Bromo-1H-[1,2,3]triazolo[4,5-b]pyrazin-1-yl)methyl]-7-fluoroquinoline

6-[(6-Bromo-1H-[1,2,3]triazolo[4,5-b]pyrazin-1-yl)methyl]-7-fluoroquinoline

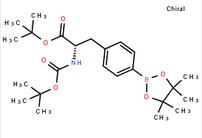

tert-butyl (S)-2-((tert-butoxycarbonyl)amino)-3-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)propanoate

tert-butyl (S)-2-((tert-butoxycarbonyl)amino)-3-(4-(4,4,5,5-tetramethyl-1,3,2-dioxaborolan-2-yl)phenyl)propanoate

![7-Trifluoromethyl-imidazo[1,2-a]pyridine 7-Trifluoromethyl-imidazo[1,2-a]pyridine](/data/attachment/201706/07/24ba6100528abe0753ad9e82ef8dc810.gif) 7-Trifluoromethyl-imidazo[1,2-a]pyridine

7-Trifluoromethyl-imidazo[1,2-a]pyridine

methyl 4-(aminomethyl)-3-chlorobenzoate

methyl 4-(aminomethyl)-3-chlorobenzoate

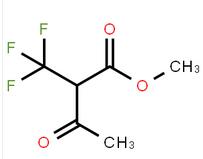

methyl 3-oxo-2-(trifluoromethyl)butanoate

methyl 3-oxo-2-(trifluoromethyl)butanoate

![2-AMino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid tert-butyl ester 2-AMino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid tert-butyl ester](/data/attachment/201706/07/22aadd4c55094254a681014935f56827.jpg) 2-AMino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid tert-butyl ester

2-AMino-4,5,6,7-tetrahydro-benzo[b]thiophene-3-carboxylic acid tert-butyl ester

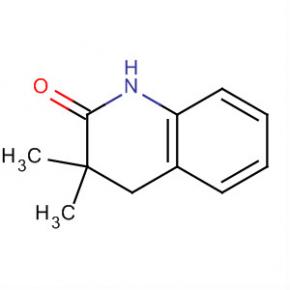

2(1H)-Quinolinone, 3,4-dihydro-3,3-dimethyl

2(1H)-Quinolinone, 3,4-dihydro-3,3-dimethyl

Methanone, (2-aMino-5-Methoxyphenyl)(4-chlorophenyl)

Methanone, (2-aMino-5-Methoxyphenyl)(4-chlorophenyl)

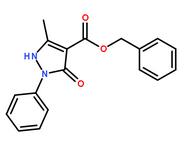

benzyl 5-methyl-3-oxo-2-phenyl-2,3-dihydro-1H-pyrazole-4-carboxylate

benzyl 5-methyl-3-oxo-2-phenyl-2,3-dihydro-1H-pyrazole-4-carboxylate

3-(1H-pyrazol-5-yl)phenol

3-(1H-pyrazol-5-yl)phenol

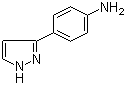

4-(1H-Pyrazol-3-yl)aniline

4-(1H-Pyrazol-3-yl)aniline

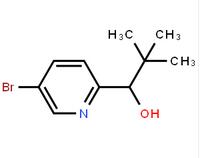

1-(5-bromo-pyridin-2-yl)-2,2-dimethyl-propan-1-ol

1-(5-bromo-pyridin-2-yl)-2,2-dimethyl-propan-1-ol

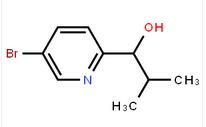

1-(5-bromo-pyridin-2-yl)-2-methyl-propan-1-ol

1-(5-bromo-pyridin-2-yl)-2-methyl-propan-1-ol

![Benzenemethanol, a-[(1S)-1-aminoethyl]-4-hydroxy-,(aR) Benzenemethanol, a-[(1S)-1-aminoethyl]-4-hydroxy-,(aR)](/data/attachment/201706/07/c4adcbada0ef372ae46cbaed643dd18e.jpg) Benzenemethanol, a-[(1S)-1-aminoethyl]-4-hydroxy-,(aR)

Benzenemethanol, a-[(1S)-1-aminoethyl]-4-hydroxy-,(aR)

![2(1H)-Quinolinone,5-[(1R)-2-amino-1-[[(1,1-dimethylethyl)dimethylsilyl]oxy]ethyl]-8-hydroxy 2(1H)-Quinolinone,5-[(1R)-2-amino-1-[[(1,1-dimethylethyl)dimethylsilyl]oxy]ethyl]-8-hydroxy](/data/attachment/201706/07/e0e9b5769a45af836d70be4140043125.gif.thumb.jpg) 2(1H)-Quinolinone,5-[(1R)-2-amino-1-[[(1,1-dimethylethyl)dimethylsilyl]oxy]ethyl]-8-hydroxy

2(1H)-Quinolinone,5-[(1R)-2-amino-1-[[(1,1-dimethylethyl)dimethylsilyl]oxy]ethyl]-8-hydroxy

![2-{[3-(4-Fluorophenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrim idin-2-yl]sulfanyl}-N-(6-methyl-1,3-benzothiazol-2-yl)acetamide 2-{[3-(4-Fluorophenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrim idin-2-yl]sulfanyl}-N-(6-methyl-1,3-benzothiazol-2-yl)acetamide](/data/attachment/201706/07/5754ee36bdfbf4148f45632422f563b9.jpg) 2-{[3-(4-Fluorophenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrim idin-2-yl]sulfanyl}-N-(6-methyl-1,3-benzothiazol-2-yl)acetamide

2-{[3-(4-Fluorophenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrim idin-2-yl]sulfanyl}-N-(6-methyl-1,3-benzothiazol-2-yl)acetamide

![2-((3-(2-methoxyphenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrimidin-2-yl)thio)-N-(6-methylbenzo[d]thiazol-2-yl)acetamide 2-((3-(2-methoxyphenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrimidin-2-yl)thio)-N-(6-methylbenzo[d]thiazol-2-yl)acetamide](/data/attachment/201706/08/47a8b3c98aef0b9ba378c4b7c6cef435.jpg) 2-((3-(2-methoxyphenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrimidin-2-yl)thio)-N-(6-methylbenzo[d]thiazol-2-yl)acetamide

2-((3-(2-methoxyphenyl)-4-oxo-3,4,6,7-tetrahydrothieno[3,2-d]pyrimidin-2-yl)thio)-N-(6-methylbenzo[d]thiazol-2-yl)acetamide

![N-(6-Methyl-2-benzothiazolyl)-2-[(3,4,6,7-tetrahydro-4-oxo-3-phenylthieno[3,2-d]pyrimidin-2-yl)thio]-acetamide N-(6-Methyl-2-benzothiazolyl)-2-[(3,4,6,7-tetrahydro-4-oxo-3-phenylthieno[3,2-d]pyrimidin-2-yl)thio]-acetamide](/data/attachment/201706/08/beda6f8f4655aa74d3646cfc7621fb20.jpg) N-(6-Methyl-2-benzothiazolyl)-2-[(3,4,6,7-tetrahydro-4-oxo-3-phenylthieno[3,2-d]pyrimidin-2-yl)thio]-acetamide

N-(6-Methyl-2-benzothiazolyl)-2-[(3,4,6,7-tetrahydro-4-oxo-3-phenylthieno[3,2-d]pyrimidin-2-yl)thio]-acetamide

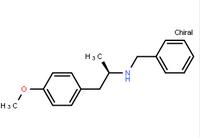

(R)-(-)-1-(4-methoxyphenyl)-2-benzylaminopropane

(R)-(-)-1-(4-methoxyphenyl)-2-benzylaminopropane

![4(3H)-Quinazolinone,7-bromo-6-chloro-3-[3-(3-hydroxy-2-piperidinyl)-2-oxopropyl] 4(3H)-Quinazolinone,7-bromo-6-chloro-3-[3-(3-hydroxy-2-piperidinyl)-2-oxopropyl]](/data/attachment/201706/09/b600ffca12695094db2c5f6045cb6685.jpg) 4(3H)-Quinazolinone,7-bromo-6-chloro-3-[3-(3-hydroxy-2-piperidinyl)-2-oxopropyl]

4(3H)-Quinazolinone,7-bromo-6-chloro-3-[3-(3-hydroxy-2-piperidinyl)-2-oxopropyl]

![9-OXO-1,2,3,9-TETRAHYDRO-PYRROLO[2,1-B]QUINAZOLINE-6-CARBOXYLIC ACID 9-OXO-1,2,3,9-TETRAHYDRO-PYRROLO[2,1-B]QUINAZOLINE-6-CARBOXYLIC ACID](/data/attachment/201706/09/d6b395bbfb23e628be7d536d9cc2b512.gif) 9-OXO-1,2,3,9-TETRAHYDRO-PYRROLO[2,1-B]QUINAZOLINE-6-CARBOXYLIC ACID

9-OXO-1,2,3,9-TETRAHYDRO-PYRROLO[2,1-B]QUINAZOLINE-6-CARBOXYLIC ACID

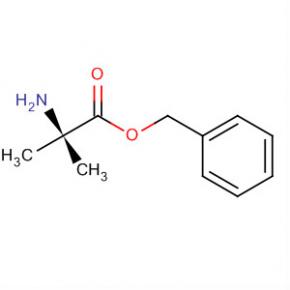

Alanine, 2-methyl-, phenylmethyl ester

Alanine, 2-methyl-, phenylmethyl ester

2-(2-TRIFLUOROMETHYL-PHENYL)-PYRROLIDINE

2-(2-TRIFLUOROMETHYL-PHENYL)-PYRROLIDINE

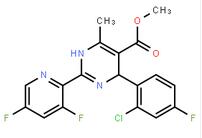

(-)-4(R)-(2-Chloro-4-fluorophenyl)-2-(3,5-difluoropyridin-2-yl)-6-methyl-1,4-dihydropyrimidine-5-carboxylic acid methyl ester

(-)-4(R)-(2-Chloro-4-fluorophenyl)-2-(3,5-difluoropyridin-2-yl)-6-methyl-1,4-dihydropyrimidine-5-carboxylic acid methyl ester

![2-Butenoic acid, 2-hydroxy-4-[5-(1-Methylethyl)-2,4-bis(phenylMethoxy)phenyl]-4-oxo-, ethyl ester 2-Butenoic acid, 2-hydroxy-4-[5-(1-Methylethyl)-2,4-bis(phenylMethoxy)phenyl]-4-oxo-, ethyl ester](/data/attachment/201706/09/11c6e17ba89840528c5461ae5350df33.gif) 2-Butenoic acid, 2-hydroxy-4-[5-(1-Methylethyl)-2,4-bis(phenylMethoxy)phenyl]-4-oxo-, ethyl ester

2-Butenoic acid, 2-hydroxy-4-[5-(1-Methylethyl)-2,4-bis(phenylMethoxy)phenyl]-4-oxo-, ethyl ester

methanone [4-amino-2-(ethylsulfanyl)pyrimidin-5-yl](2,3-difluoro-6-methoxyphenyl)methanone](/data/attachment/201706/09/ca947be16560699c92609cd96b352c02.png.thumb.jpg) [4-amino-2-(ethylsulfanyl)pyrimidin-5-yl](2,3-difluoro-6-methoxyphenyl)methanone

[4-amino-2-(ethylsulfanyl)pyrimidin-5-yl](2,3-difluoro-6-methoxyphenyl)methanone

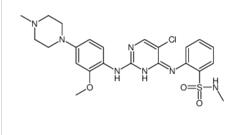

![Benzenesulfonamide, 2-[(5-bromo-2-chloro-4-pyrimidinyl)amino]-N-methyl Benzenesulfonamide, 2-[(5-bromo-2-chloro-4-pyrimidinyl)amino]-N-methyl](/data/attachment/201706/10/ce0d621896c03bdb67e3b184103e84ff.png.thumb.jpg) Benzenesulfonamide, 2-[(5-bromo-2-chloro-4-pyrimidinyl)amino]-N-methyl

Benzenesulfonamide, 2-[(5-bromo-2-chloro-4-pyrimidinyl)amino]-N-methyl

ALK inhibitor 2

ALK inhibitor 2

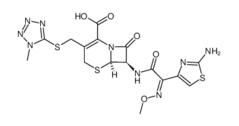

Cefmenoxime hydrochloride

Cefmenoxime hydrochloride

(S)-N-1-Boc-N-4-Cbz-2-piperazinecarboxylic acid

(S)-N-1-Boc-N-4-Cbz-2-piperazinecarboxylic acid

Avermectin

Avermectin

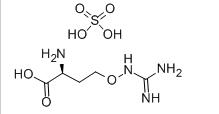

L-CANAVANINE SULFATE

L-CANAVANINE SULFATE

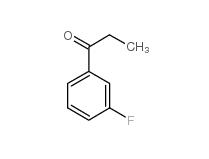

3-Fluoropropiophenone 455-67-4

3-Fluoropropiophenone 455-67-4

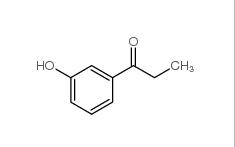

3-Hydroxypropiophenone 13103-80-5

3-Hydroxypropiophenone 13103-80-5

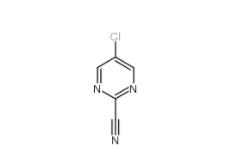

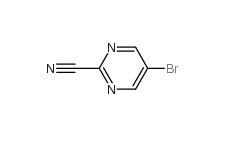

2-Cyano-5-chloropyrimidine 38275-56-8

2-Cyano-5-chloropyrimidine 38275-56-8

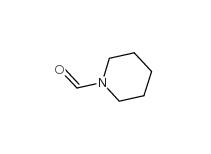

N-Formylpiperidine 2591-86-8

N-Formylpiperidine 2591-86-8

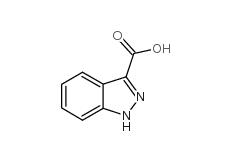

Indazole-3-carboxylic acid 4498-67-3

Indazole-3-carboxylic acid 4498-67-3

5-Bromo-2-cyanopyrimidine 38275-57-9

5-Bromo-2-cyanopyrimidine 38275-57-9

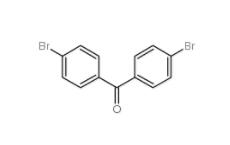

4,4-Dibromobenzophenone 3988-03-2

4,4-Dibromobenzophenone 3988-03-2

![1,2,3,4-Tetrahydro-benzo[b]azepin-5-one 1127-74-8 1,2,3,4-Tetrahydro-benzo[b]azepin-5-one 1127-74-8](/data/attachment/201901/28/b183df1e648eca4396ad0d319a1254bc.jpg) 1,2,3,4-Tetrahydro-benzo[b]azepin-5-one 1127-74-8

1,2,3,4-Tetrahydro-benzo[b]azepin-5-one 1127-74-8

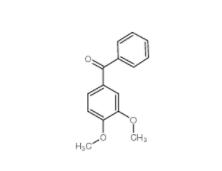

4038-14-6,(3,4-dimethoxyphenyl)-phenylmethanone 4038-14-6

4038-14-6,(3,4-dimethoxyphenyl)-phenylmethanone 4038-14-6

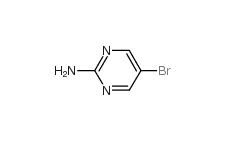

2-Amino-5-bromopyrimidine 7752-82-1

2-Amino-5-bromopyrimidine 7752-82-1

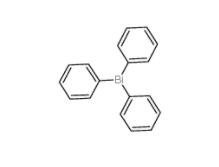

Triphenylbismuth 603-33-8

Triphenylbismuth 603-33-8

![3-Ethynylimidazo[1,2-a]pyridine 943320-53-4 3-Ethynylimidazo[1,2-a]pyridine 943320-53-4](/data/attachment/201901/28/d6294d1dabcee85ee04792b0c0e255c0.jpg) 3-Ethynylimidazo[1,2-a]pyridine 943320-53-4

3-Ethynylimidazo[1,2-a]pyridine 943320-53-4

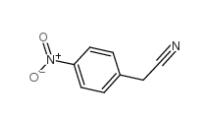

4-Nitrophenylacetonitrile 555-21-5

4-Nitrophenylacetonitrile 555-21-5

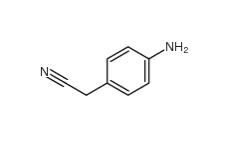

2-(4-aminophenyl)acetonitrile 3544-25-0

2-(4-aminophenyl)acetonitrile 3544-25-0

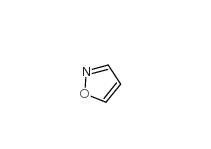

isoxazole 288-14-2

isoxazole 288-14-2

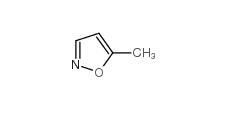

5-Methylisoxazole 5765-44-6

5-Methylisoxazole 5765-44-6

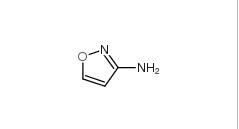

3-Aminoisoxazole 1750-42-1

3-Aminoisoxazole 1750-42-1

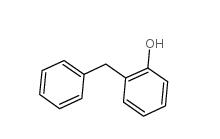

2-Hydroxydiphenylmethane 28994-41-4

2-Hydroxydiphenylmethane 28994-41-4

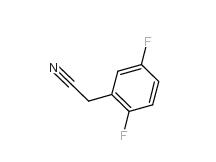

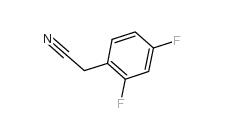

2,5-Difluorobenzyl Cyanide 69584-87-8

2,5-Difluorobenzyl Cyanide 69584-87-8

2,4-Difluorophenylacetonitrile 656-35-9

2,4-Difluorophenylacetonitrile 656-35-9

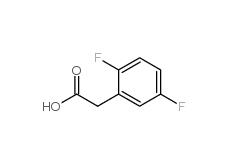

2,5-Difluorophenylacetic acid 85068-27-5

2,5-Difluorophenylacetic acid 85068-27-5

2,4-Difluorophenylacetic acid 81228-09-3

2,4-Difluorophenylacetic acid 81228-09-3

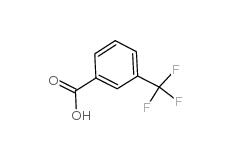

3-trifluoromethylbenzoic acid 454-92-2

3-trifluoromethylbenzoic acid 454-92-2

![2-[3-(trifluoromethyl)phenyl]acetonitrile 2338-76-3 2-[3-(trifluoromethyl)phenyl]acetonitrile 2338-76-3](/data/attachment/201901/29/22b99245cb0bbcd2d86f238725d9fb9d.jpg) 2-[3-(trifluoromethyl)phenyl]acetonitrile 2338-76-3

2-[3-(trifluoromethyl)phenyl]acetonitrile 2338-76-3

![2-[3-(trifluoromethyl)phenyl]acetic acid 351-35-9 2-[3-(trifluoromethyl)phenyl]acetic acid 351-35-9](/data/attachment/201901/29/7dbc74a276a4c124b9460222442fd80f.jpg) 2-[3-(trifluoromethyl)phenyl]acetic acid 351-35-9

2-[3-(trifluoromethyl)phenyl]acetic acid 351-35-9

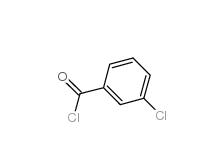

3-Chlorobenzoyl chloride 618-46-2

3-Chlorobenzoyl chloride 618-46-2

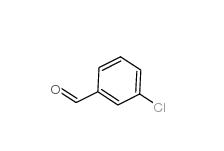

3-Chlorobenzaldehyde 587-04-2

3-Chlorobenzaldehyde 587-04-2

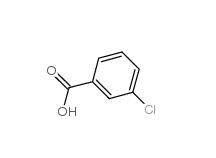

3-chlorobenzoic acid 535-80-8

3-chlorobenzoic acid 535-80-8

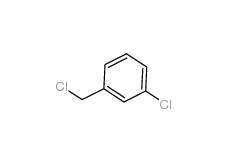

3-Chlorobenzyl chloride 620-20-2

3-Chlorobenzyl chloride 620-20-2

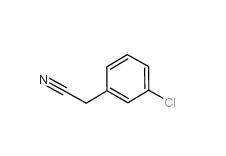

3-Chlorobenzyl cyanide 1529-41-5

3-Chlorobenzyl cyanide 1529-41-5

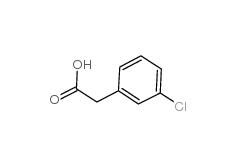

2-(3-chlorophenyl)acetic acid 1878-65-5

2-(3-chlorophenyl)acetic acid 1878-65-5

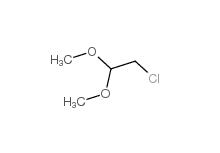

Dimethylchloroacetal 97-97-2

Dimethylchloroacetal 97-97-2

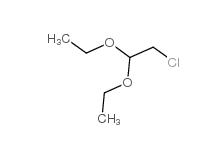

Chloroacetaldehyde diethyl acetal 621-62-5

Chloroacetaldehyde diethyl acetal 621-62-5

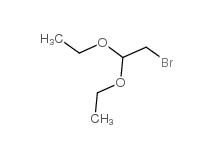

2-bromo-1,1-diethoxyethane 2032-35-1

2-bromo-1,1-diethoxyethane 2032-35-1

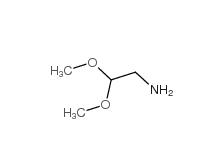

2,2-dimethoxyethanamine 22483-09-6

2,2-dimethoxyethanamine 22483-09-6

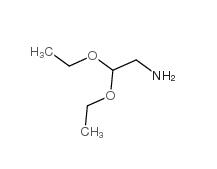

2,2-Diethoxyethylamine 645-36-3

2,2-Diethoxyethylamine 645-36-3

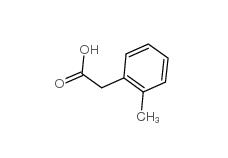

2-Methylphenylacetic acid 644-36-0

2-Methylphenylacetic acid 644-36-0

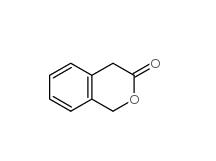

3-Isochromanone 4385-35-7

3-Isochromanone 4385-35-7

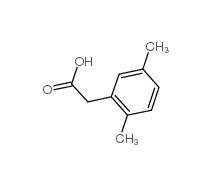

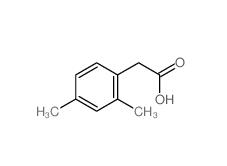

2,5-Dimethylphenylacetic acid 13612-34-5

2,5-Dimethylphenylacetic acid 13612-34-5

2,4-Dimethylphenylacetic Acid 6331-04-0

2,4-Dimethylphenylacetic Acid 6331-04-0

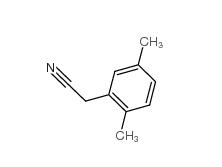

2,5-Dimethylphenylacetonitrile 16213-85-7

2,5-Dimethylphenylacetonitrile 16213-85-7

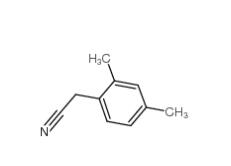

2,4-Dimethylphenylacetonitrile 68429-53-8

2,4-Dimethylphenylacetonitrile 68429-53-8

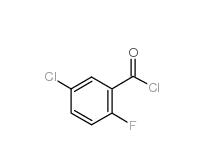

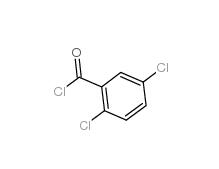

5-CHLORO-2-FLUOROBENZOYL CHLORIDE 394-29-6

5-CHLORO-2-FLUOROBENZOYL CHLORIDE 394-29-6

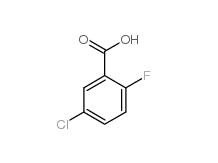

5-Chloro-2-fluorobenzoic acid 394-30-9

5-Chloro-2-fluorobenzoic acid 394-30-9

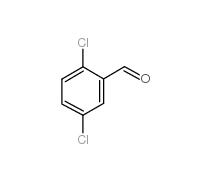

2,5-Dichlorobenzaldehyde 6361-23-5

2,5-Dichlorobenzaldehyde 6361-23-5

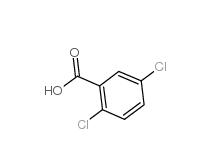

2,5-Dichlorobenzoic acid 50-79-3

2,5-Dichlorobenzoic acid 50-79-3

2,5-DICHLOROBENZOYL CHLORIDE 2905-61-5

2,5-DICHLOROBENZOYL CHLORIDE 2905-61-5

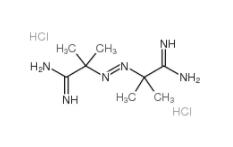

2,2-Azobis(2-methylpropionamidine) dihydrochloride 2997-92-4

2,2-Azobis(2-methylpropionamidine) dihydrochloride 2997-92-4

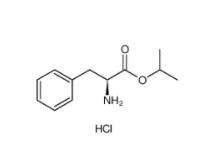

L-Phenylalanine, 1-methylethyl ester, hydrochloride 95585-78-7

L-Phenylalanine, 1-methylethyl ester, hydrochloride 95585-78-7

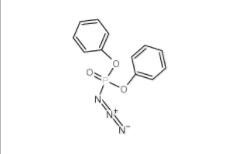

Diphenylphosphoryl azide 26386-88-9

Diphenylphosphoryl azide 26386-88-9

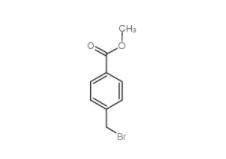

Methyl 4-(bromomethyl)benzoate 2417-72-3

Methyl 4-(bromomethyl)benzoate 2417-72-3

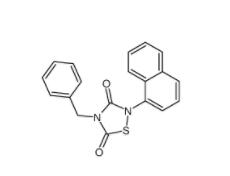

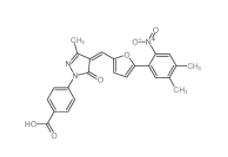

Tideglusib 865854-05-3

Tideglusib 865854-05-3

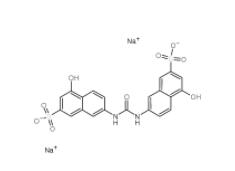

Disodium 7,7-(carbonyldiimino)bis(4-hydroxynaphthalene-2-sulphonate) 20324-87-2

Disodium 7,7-(carbonyldiimino)bis(4-hydroxynaphthalene-2-sulphonate) 20324-87-2

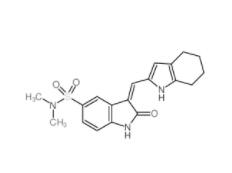

SU 6656 330161-87-0

SU 6656 330161-87-0

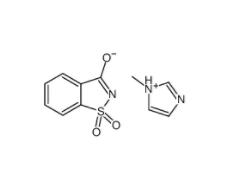

Saccharin 1-methylimidazole 482333-74-4

Saccharin 1-methylimidazole 482333-74-4

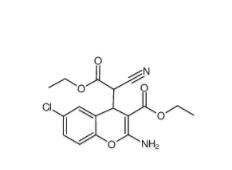

CeMMEC13 1790895-25-8

CeMMEC13 1790895-25-8

Rabusertib 911222-45-2

Rabusertib 911222-45-2

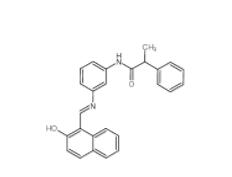

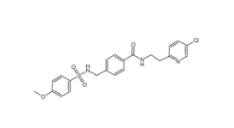

Salermide 1105698-15-4

Salermide 1105698-15-4

EST 88321-09-9

EST 88321-09-9

SC79 305834-79-1

SC79 305834-79-1

C646 328968-36-1

C646 328968-36-1

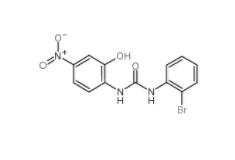

1-(2-bromophenyl)-3-(2-hydroxy-4-nitrophenyl)urea 182498-32-4

1-(2-bromophenyl)-3-(2-hydroxy-4-nitrophenyl)urea 182498-32-4

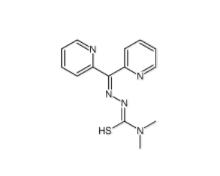

Dp44mT 152095-12-0

Dp44mT 152095-12-0

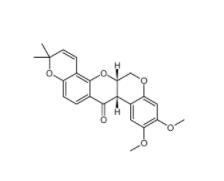

Deguelin 522-17-8

Deguelin 522-17-8

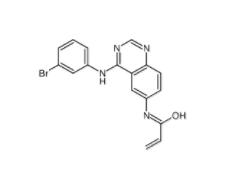

PD168393 194423-15-9

PD168393 194423-15-9

YO01027 209984-56-5

YO01027 209984-56-5

DC10539 1822358-25-7

DC10539 1822358-25-7

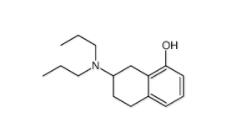

8-OH-DPAT 78950-78-4

8-OH-DPAT 78950-78-4

YU238259 1943733-16-1

YU238259 1943733-16-1

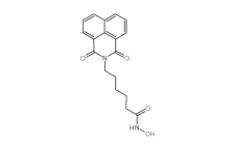

Scriptaid 287383-59-9

Scriptaid 287383-59-9

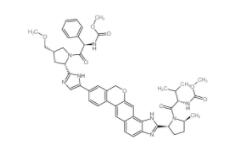

Velpatasvir 1377049-84-7

Velpatasvir 1377049-84-7

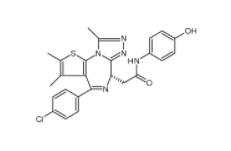

OTX015 202590-98-5

OTX015 202590-98-5

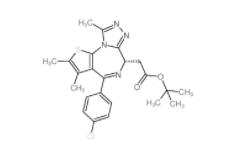

(+)-JQ-1 1268524-70-4

(+)-JQ-1 1268524-70-4

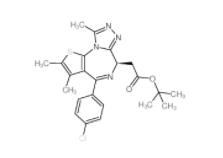

(-)-JQ-1 1268524-71-5

(-)-JQ-1 1268524-71-5

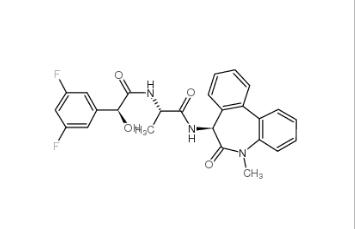

LY 900009 209984-68-9

LY 900009 209984-68-9

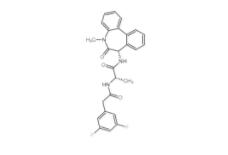

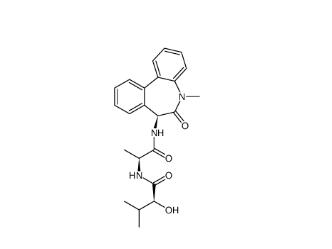

LY-411575 209984-57-6

LY-411575 209984-57-6

![(4-nitrophenyl) 4-[bis(1,3-benzodioxol-5-yl)-hydroxymethyl]piperidine-1-carboxylate 1101854-58-3 (4-nitrophenyl) 4-[bis(1,3-benzodioxol-5-yl)-hydroxymethyl]piperidine-1-carboxylate 1101854-58-3](/data/attachment/201903/22/9e81dae7e0bdec56ac6052b1872d9626.jpg) (4-nitrophenyl) 4-[bis(1,3-benzodioxol-5-yl)-hydroxymethyl]piperidine-1-carboxylate 1101854-58-3

(4-nitrophenyl) 4-[bis(1,3-benzodioxol-5-yl)-hydroxymethyl]piperidine-1-carboxylate 1101854-58-3

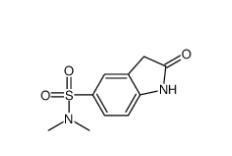

N,N-dimethyl-2-oxo-1,3-dihydroindole-5-sulfonamide 170565-89-6

N,N-dimethyl-2-oxo-1,3-dihydroindole-5-sulfonamide 170565-89-6

![5,6,11,12-tetrahydrodibenzo[1,2-b:1,2-g][8]annulene 1460-59-9 5,6,11,12-tetrahydrodibenzo[1,2-b:1,2-g][8]annulene 1460-59-9](/data/attachment/201903/23/50930df6d55412ac8f4da0724b497aaf.jpg) 5,6,11,12-tetrahydrodibenzo[1,2-b:1,2-g][8]annulene 1460-59-9

5,6,11,12-tetrahydrodibenzo[1,2-b:1,2-g][8]annulene 1460-59-9

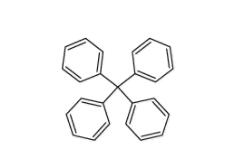

Tetraphenylmethane 630-76-2

Tetraphenylmethane 630-76-2

![2-chloro-6-[(2R)-2-hydroxy-3-[(2-methyl-1-naphthalen-2-ylpropan-2-yl)amino]propoxy]benzonitrile 284035-33-2 2-chloro-6-[(2R)-2-hydroxy-3-[(2-methyl-1-naphthalen-2-ylpropan-2-yl)amino]propoxy]benzonitrile 284035-33-2](/data/attachment/201903/23/7e63bafe6c4b7e146e00c57dfca99672.jpg) 2-chloro-6-[(2R)-2-hydroxy-3-[(2-methyl-1-naphthalen-2-ylpropan-2-yl)amino]propoxy]benzonitrile 284035-33-2

2-chloro-6-[(2R)-2-hydroxy-3-[(2-methyl-1-naphthalen-2-ylpropan-2-yl)amino]propoxy]benzonitrile 284035-33-2

1616380-54-1

1616380-54-1

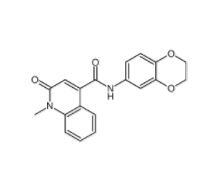

![N-(2,3-dihydrobenzo[b][1,4]dioxin-6-yl)-2-methyl-1-oxo-1,2-dihydroisoquinoline-4-carboxamide 440662-09-9 N-(2,3-dihydrobenzo[b][1,4]dioxin-6-yl)-2-methyl-1-oxo-1,2-dihydroisoquinoline-4-carboxamide 440662-09-9](/data/attachment/201903/23/e26baac537719657acd9f1f55568401d.jpg) N-(2,3-dihydrobenzo[b][1,4]dioxin-6-yl)-2-methyl-1-oxo-1,2-dihydroisoquinoline-4-carboxamide 440662-09-9

N-(2,3-dihydrobenzo[b][1,4]dioxin-6-yl)-2-methyl-1-oxo-1,2-dihydroisoquinoline-4-carboxamide 440662-09-9

![N-[2-[2-(4-chlorophenyl)-1,3-thiazol-4-yl]ethyl]butanamide 932986-18-0 N-[2-[2-(4-chlorophenyl)-1,3-thiazol-4-yl]ethyl]butanamide 932986-18-0](/data/attachment/201903/23/7d2bbd100c8322ae16168937617e1bb2.jpg) N-[2-[2-(4-chlorophenyl)-1,3-thiazol-4-yl]ethyl]butanamide 932986-18-0

N-[2-[2-(4-chlorophenyl)-1,3-thiazol-4-yl]ethyl]butanamide 932986-18-0

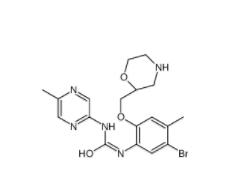

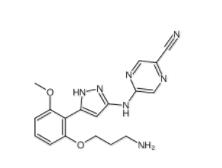

5-(5-(2-(3-aminopropoxy)-6-methoxyphenyl)-1H-pyrazol-3-ylamino)pyrazine-2-carbonitrile 1234015-52-1

5-(5-(2-(3-aminopropoxy)-6-methoxyphenyl)-1H-pyrazol-3-ylamino)pyrazine-2-carbonitrile 1234015-52-1

![3-Methyl-3-[(1E)-2-phenylethenyl]-3,2:5,2:5,3-quaterpyridine 1651890-44-6 3-Methyl-3-[(1E)-2-phenylethenyl]-3,2:5,2:5,3-quaterpyridine 1651890-44-6](/data/attachment/201903/23/07bf6fd99e81033df0c83039ccdde036.jpg) 3-Methyl-3-[(1E)-2-phenylethenyl]-3,2:5,2:5,3-quaterpyridine 1651890-44-6

3-Methyl-3-[(1E)-2-phenylethenyl]-3,2:5,2:5,3-quaterpyridine 1651890-44-6

![3-[4-(Dimethylamino)-3-biphenylyl]-1,1-dimethylure 1469924-27-3 3-[4-(Dimethylamino)-3-biphenylyl]-1,1-dimethylure 1469924-27-3](/data/attachment/201903/23/f69ad7342d131146640e0c88f73e9a25.jpg) 3-[4-(Dimethylamino)-3-biphenylyl]-1,1-dimethylure 1469924-27-3

3-[4-(Dimethylamino)-3-biphenylyl]-1,1-dimethylure 1469924-27-3

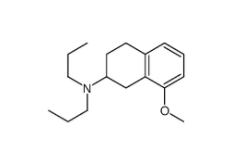

8-Methoxy-N,N-dipropyl-1,2,3,4-tetrahydro-2-naphthalenamine 3897-94-7

8-Methoxy-N,N-dipropyl-1,2,3,4-tetrahydro-2-naphthalenamine 3897-94-7

![4-{4-[(4-{[3-(Acryloylamino)phenyl]amino}-5-fluoro-2-pyrimidinyl) amino]phenoxy}-N-methyl-2-pyridinecarboxamide 1202759-32-7 4-{4-[(4-{[3-(Acryloylamino)phenyl]amino}-5-fluoro-2-pyrimidinyl) amino]phenoxy}-N-methyl-2-pyridinecarboxamide 1202759-32-7](/data/attachment/201903/23/bb4110673d0676f81860d708092eb660.jpg) 4-{4-[(4-{[3-(Acryloylamino)phenyl]amino}-5-fluoro-2-pyrimidinyl) amino]phenoxy}-N-methyl-2-pyridinecarboxamide 1202759-32-7

4-{4-[(4-{[3-(Acryloylamino)phenyl]amino}-5-fluoro-2-pyrimidinyl) amino]phenoxy}-N-methyl-2-pyridinecarboxamide 1202759-32-7

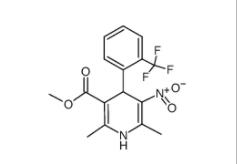

1,4-Dihydro-2,6-dimethyl-3-nitro-4-(2-trifluoromethylphenyl)-pyridine-5-carboxylic acid methyl ester 71145-03-4

1,4-Dihydro-2,6-dimethyl-3-nitro-4-(2-trifluoromethylphenyl)-pyridine-5-carboxylic acid methyl ester 71145-03-4

![2-[[3-[[2-(dimethylamino)phenyl]methyl]-2-pyridin-4-yl-1,3-diazinan-1-yl]methyl]-N,N-dimethylaniline 500579-04-4 2-[[3-[[2-(dimethylamino)phenyl]methyl]-2-pyridin-4-yl-1,3-diazinan-1-yl]methyl]-N,N-dimethylaniline 500579-04-4](/data/attachment/201903/23/b396a2326dddb511aae497b01fbd4c77.jpg) 2-[[3-[[2-(dimethylamino)phenyl]methyl]-2-pyridin-4-yl-1,3-diazinan-1-yl]methyl]-N,N-dimethylaniline 500579-04-4

2-[[3-[[2-(dimethylamino)phenyl]methyl]-2-pyridin-4-yl-1,3-diazinan-1-yl]methyl]-N,N-dimethylaniline 500579-04-4

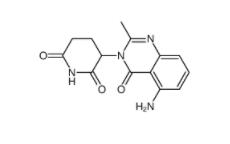

CC-122 1015474-32-4

CC-122 1015474-32-4

Bioymifi 1420071-30-2

Bioymifi 1420071-30-2

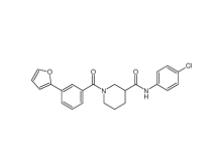

N-(4-chlorophenyl)-1-(3-(furan-2-yl)benzoyl)piperidine-3-carboxamide 1443437-74-8

N-(4-chlorophenyl)-1-(3-(furan-2-yl)benzoyl)piperidine-3-carboxamide 1443437-74-8

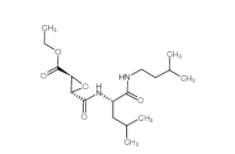

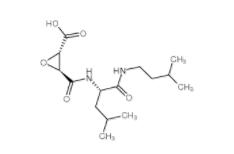

E-64C 76684-89-4

E-64C 76684-89-4

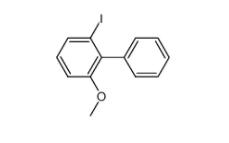

2-iodo-6-methoxybiphenyl 84253-78-1

2-iodo-6-methoxybiphenyl 84253-78-1

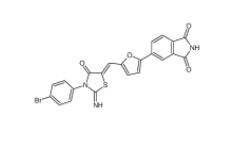

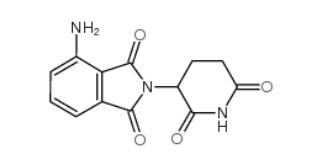

pomalidomide 19171-19-8

pomalidomide 19171-19-8

4EP-Directory listing

4EP-Directory listing

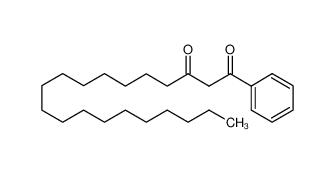

Stearoylbenzoylmethane 58446-52-9

Stearoylbenzoylmethane 58446-52-9

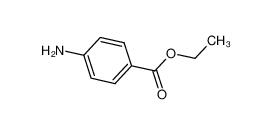

benzocaine 94-09-7

benzocaine 94-09-7

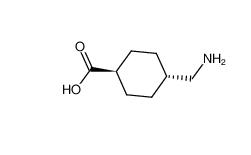

tranexamic acid 1197-18-8

tranexamic acid 1197-18-8

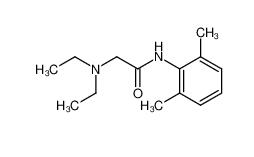

lidocaine 137-58-6

lidocaine 137-58-6

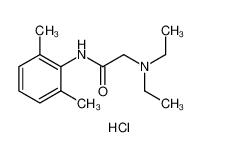

lidocaine hydrochloride 73-78-9

lidocaine hydrochloride 73-78-9

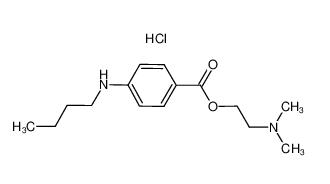

Tetracaine hydrochloride 136-47-0

Tetracaine hydrochloride 136-47-0

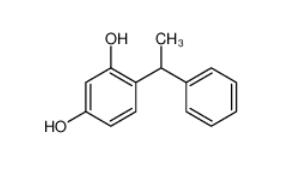

4-(1-phenylethyl)benzene-1,3-diol 85-27-8

4-(1-phenylethyl)benzene-1,3-diol 85-27-8

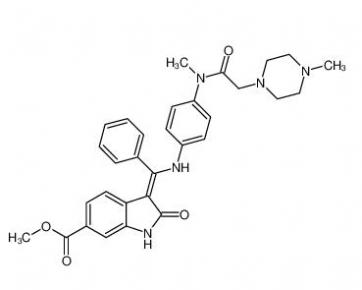

Nintedanib 656247-17-5

Nintedanib 656247-17-5

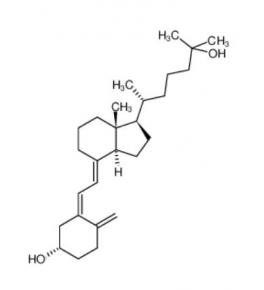

calcidiol 19356-17-3

calcidiol 19356-17-3

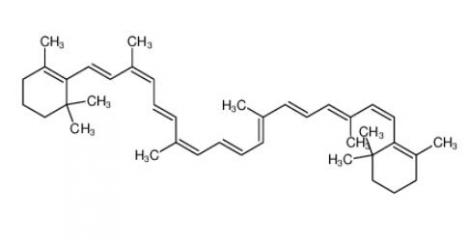

β-carotene 7235-40-7

β-carotene 7235-40-7

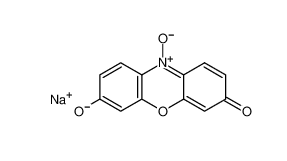

Resazurin sodium salt 62758-13-8

Resazurin sodium salt 62758-13-8

4704-94-3 2-(HYDROXYMETHYL)-1,3-PROPANEDIOL

4704-94-3 2-(HYDROXYMETHYL)-1,3-PROPANEDIOL

L-Tyrosine 60-18-4

L-Tyrosine 60-18-4

L-Histidine 71-00-1

L-Histidine 71-00-1

3,5-Bis(bromomethyl)toluene 19294-04-3

3,5-Bis(bromomethyl)toluene 19294-04-3

Bis(4-methylphenyl)methanol 885-77-8

Bis(4-methylphenyl)methanol 885-77-8

5-Fluoroorotic Acid Hydrate 207291-81-4

5-Fluoroorotic Acid Hydrate 207291-81-4

1,3,5-Trimethyl-1H-pyrazole-4-carboxylic acid 1125-29-7

1,3,5-Trimethyl-1H-pyrazole-4-carboxylic acid 1125-29-7

5-Amino-2-chloro-4-fluorophenol 84478-72-8

5-Amino-2-chloro-4-fluorophenol 84478-72-8

Gabapentin-lactam 64744-50-9

Gabapentin-lactam 64744-50-9

1EP-Directory listing

1EP-Directory listing

![[2-(aminocarbonyl)phenyl]acetic acid 23362-56-3 [2-(aminocarbonyl)phenyl]acetic acid 23362-56-3](/data/attachment/202211/10/9756043560e11c17cf958f3ed54d541a.png.thumb.jpg) [2-(aminocarbonyl)phenyl]acetic acid 23362-56-3

[2-(aminocarbonyl)phenyl]acetic acid 23362-56-3

2-(5-Methyl-2-phenyl-1,3-oxazol-4-yl)ethan-1-ol 103788-65-4

2-(5-Methyl-2-phenyl-1,3-oxazol-4-yl)ethan-1-ol 103788-65-4

2-Amino-6-cyclopropylamino-9H-purine 120503-69-7

2-Amino-6-cyclopropylamino-9H-purine 120503-69-7

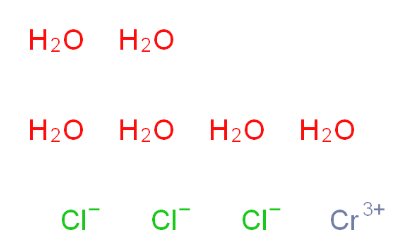

Chromic chloride hexahydrate 10060-12-5

Chromic chloride hexahydrate 10060-12-5

2EP-Directory listing 2

2EP-Directory listing 2

3EP-Directory listing 3

3EP-Directory listing 3